FrontierPS recognizes that in today’s Oil and Gas Industry, the volume of well and facilities field data generated is overwhelming; the key to unlocking the value of this data is through effective analysis – this ensures that operational decisions are fact, as opposed to opinion based.

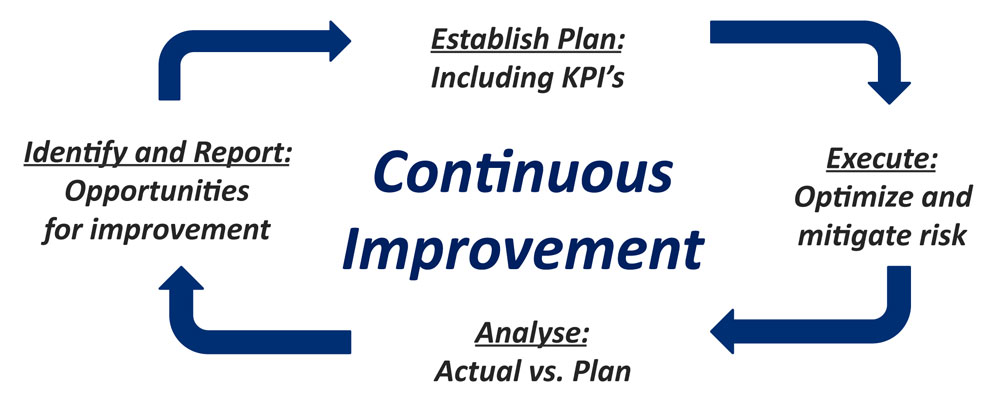

FrontierPS recognizes the value of effective data analysis and builds this into all work flows in the form of a continuous improvement process:

The continuous improvement process is premised on the fact that one cannot improve that which is not measured!

Examples where data analysis techniques are used towards continuous improvement:

Lookback Variance Analysis:

Every operation can be analysed using variance analysis techniques. Actual time/cost of all events during operations can be compared to the planned time/cost of the event and any measured variance categorized into one of the following:

- Non-Productive Time (NPT)

- Change of Scope

- Estimating Variance

Categorizing variance in such a way ensures the project staff know where to focus efforts to improve subsequent operations.

Technical Limit:

When planning upcoming operations, a composite of historical time and/or cost by event is compiled that identifies relative performance on each event. This composite is presented in such a way as to present the theoretical best performance for the operation which is fully achievable as it is based on actual individual performance. This method is an excellent means to set performance targets for a team.

If you have more data than you know what to do with, FrontierPS has the tools and expertise to analyse the data in such a way as to create knowledge that is in turn used as an effective means to improve all upcoming operations.